Bathroom Repair Tutor – Revised 120922 › Forums › Toilets › Iron toilet flange

Well I’m deep into this bathroom project. The floor was so rotten that I had to remove two layers of 3/4 inch tongue & groove and took it down to the floor joists. It must have been leaking for decades. Looks like part of of problem is that one of the joists was cut to install the toilet drain which made the floor sag and probably made the toilet leak. I sistered the joist and it looks pretty solid now.

If you guys have any experience with old school, lead & oakum caulked, cast iron toilet flanges I could use some advice. I’m dealing with one that’s pretty rusty but maybe serviceable. I watched a youtube video where a guy removed one of these with brute force – ginder & chisels, and replaced with PVC flange. I’m willing to give it a try if necessary but I’ve never dealt with one of these before so I don’t know how to judge how good is good enough and whether I should just use it as is and hope for the best. Photos attached. Any thoughts?

Hey Edward,

Ya, they definitely hacked that joist all they way through!

So I would probably take a grinder and cut the flange in a few places to the pipe (being careful not to cut the actual 90 degree elbow) and then smack the flange off with a hammer. It should come off fairly easily since its soldered with lead.

Then install the plywood, tile underlayment, and tile closely to the waste pipe.

After tile you could then install a push-in type flange that will sit on top of the tile (you will need to drill holes through tile to anchor screws into subfloor)

I like these push in type since it has adjustment screws to tighten the rubber gasket to caste iron

Just curious, are you planning to replace the galvanized water supplies everywhere? I would recommend that while you have everything opened up. Galvanized will eventually fail….

thanks

steve

The good news is I got the iron flange off okay. I bought an ABS insert flange at Lowe’s – they didn’t have the kind with adjustment screws to expand the gasket, on this one the plastic insert is threaded with a tapered thread and the rubber gasket has matching thread and screws on the flange like a nut. The gasket expands as you rotate the flange & the gasket runs up the tapered threads. I think it will work okay except I ran into another snag.

The top surface of the old iron flange was flush with the top of the pipe and it was about the right height to fasten to the floor. The new flange sits higher because it cannot be flush with the pipe – it will leave about a 1/2 inch gap between the floor/flange mating surfaces. If I shim the gap I think the throne becomes a rocking chair. We’re doing vinyl floor, not tile. As far as a I can figure the most practical solution is to add another 1/2 inch layer of subfloor so as to raise the whole toilet up relative to the pipe. I think that will allow the flange to fasten to floor and not be too high for the toilet. This must be a common issue with these things. Do you see any better solution or any downside to mine?

Hey Edward, sorry for delayed response

So yes, this is a typical situation, but normally not an issue when tiling.

And the additional 1/2″ layer will solve the problem for sure

Other alternative is too use a good metal blade on a sawzall and cut the 1/2″ off of the caste iron pipe (cutting flush with subfloor), then run all vinyl and install the push-in fitting on top

steve

Glad to see I’m not the only one that runs into pandoras box of complications. It appears you are over a basement area. I would consider eliminating the cast iron all the way to a convenient point in the basement with whatever appropriate PVC transitions are required.

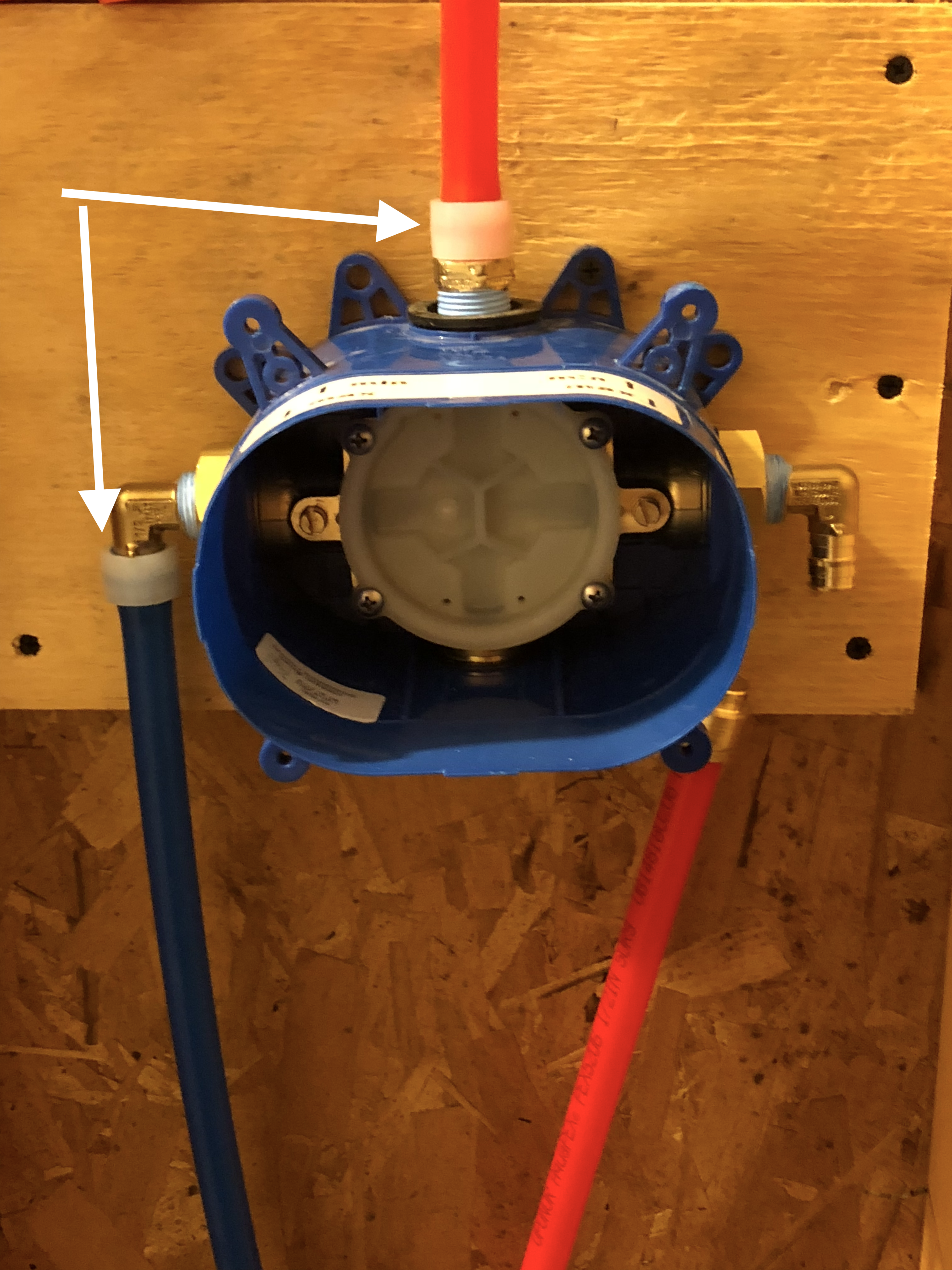

I recently discovered Pro PEX plumbing on my project. The would be PEX-A not B and Uponor expansion fittings. It’s used extensively in Europe and apparently being rapidly adapted by commercial plumbers in the states. This would be used for all your new water supply lines . The fittings require a specialized expansion tool. The fittings will not fail , corrode and or crack in time like the classic metal crimp type can under the right conditions.

metal crimp type can under the right conditions.